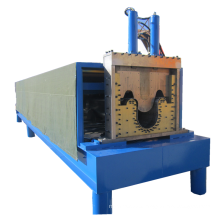

Suspension ceiling grid wall angle roll forming machine

Product Description

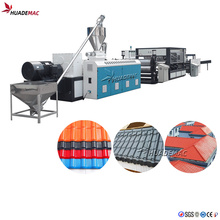

Jiangyin Bangnuo Machinery Co., Ltd. is a professional manufacturer dedicated Color light steel construction, C, Z steel equipment and rolling, bending molding equipment enterprises, with the design and manufacture of various types of steel sheet thickness roll forming production line strength. Pressed tile color steel plate and C, Z purlin products are widely used in various types of large and small industrial plants, warehouses, residential and high-rise buildings. With economic development, building light steel building applications on the growing popularity of the increasing demand for production equipment, production equipment automation requirements are also increasing, company investment, research and development of various types of color steel pressure plate (W) production line and C, Z-beam (purlin) production equipment, the use of simple, improve productivity, reduce production costs. Various existing models of steel pressure plate (W) C, Z-beam (purlin) automatic control production line are at the leading position at home and abroad, with a compact structure, reasonable design, constantly updated progress and much Strut Builders and products the favor and praise.

Company specializing in the production of Dagong machines, floor plate machine, guardrail plate machine, corrugated tile machine, Shearing Machine, sub-board machine, highway guardrail, tile machine equipment, automatic tile press, iron Piva machine, iron tile machine, all automatic C-shaped steel machine, glazed tile machine.

Composition of machine:

1. 3T manual de-coiler

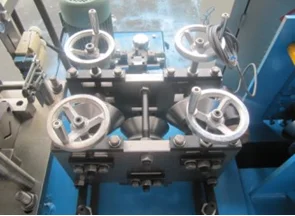

2. Feeding→roll forming→rectify device→post cutting

3. Output table

4. Hydraulic station

5. Control desk

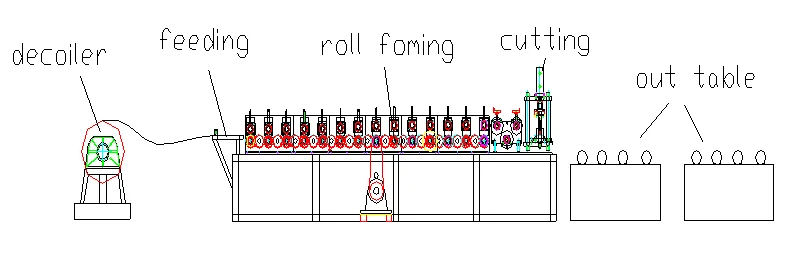

Profile, layout & production flow:

Profile thickness 0.4-0.8mm GI sheet

Size: 100×100mm

Following profile in only for customer reference, the exactly will be confirmed by customer

Layout of machine(only for reference, the exactly one will be send to customer in 20 days after confirmed order)

Working direction base on customer request:

The production flow of equipment:

De-coiler→feeding→roll forming→rectify→post cutting →output table

Pre-sales service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-sales service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Product Categories : TILE FORMING MACHINE

Premium Related Products