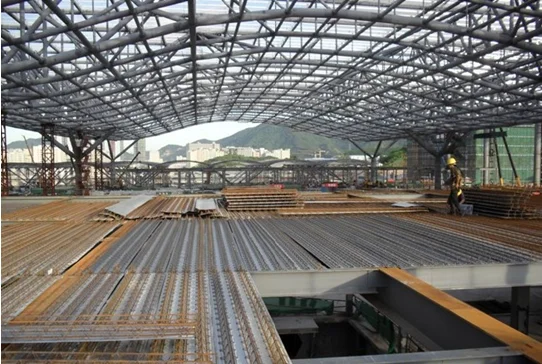

Composite Steel Floor Deck Production Line/Steel structural floor forming machine rolling making line

Product Description

Jiangyin Bangnuo Machinery Co., Ltd. is a professional manufacturer dedicated Color light steel construction, C, Z steel equipment and rolling, bending molding equipment enterprises, with the design and manufacture of various types of steel sheet thickness roll forming production line strength. Pressed tile color steel plate and C, Z purlin products are widely used in various types of large and small industrial plants, warehouses, residential and high-rise buildings. With economic development, building light steel building applications on the growing popularity of the increasing demand for production equipment, production equipment automation requirements are also increasing, company investment, research and development of various types of color steel pressure plate (W) production line and C, Z-beam (purlin) production equipment, the use of simple, improve productivity, reduce production costs. Various existing models of steel pressure plate (W) C, Z-beam (purlin) automatic control production line are at the leading position at home and abroad, with a compact structure, reasonable design, constantly updated progress and much Strut Builders and products the favor and praise.

Company specializing in the production of Dagong machines, floor plate machine, guardrail plate machine, corrugated tile machine, Shearing Machine, sub-board machine, highway guardrail, tile machine equipment, automatic tile press, iron Piva machine, iron tile machine, all automatic C-shaped steel machine, glazed tile machine.

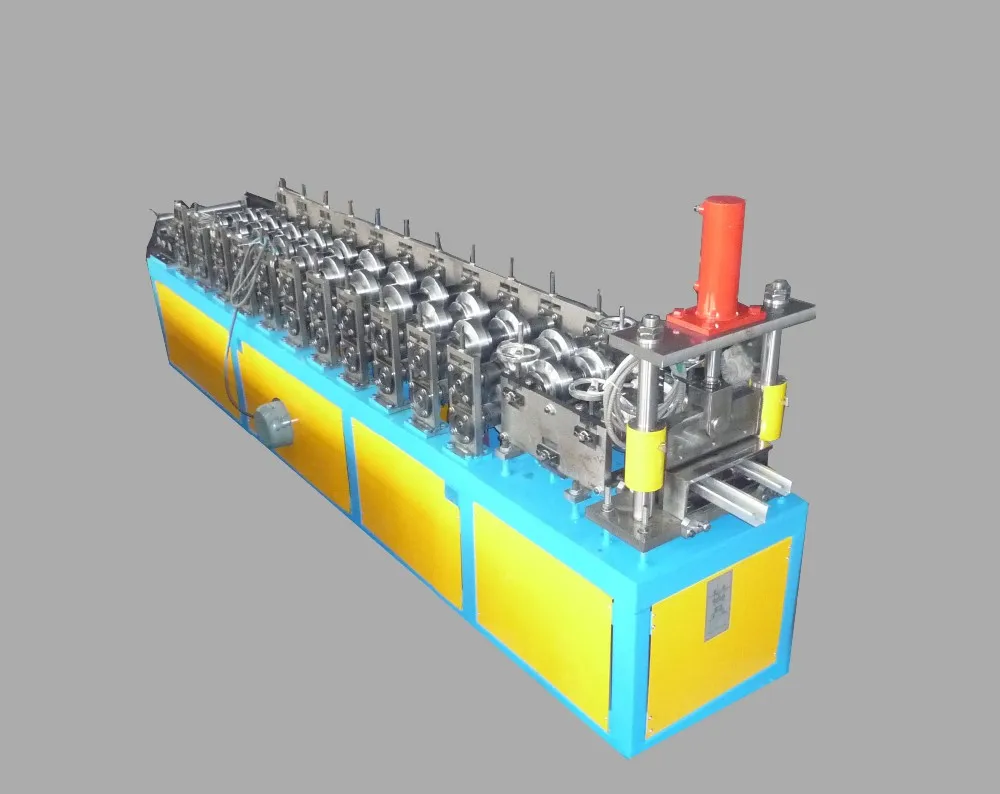

Composition of machine:

1. 5T manual DECOILER

2. Feeding→forming station→Post cutting system

3. Output table

4. Hydraulic station

5. Control desk

6. Spare part list

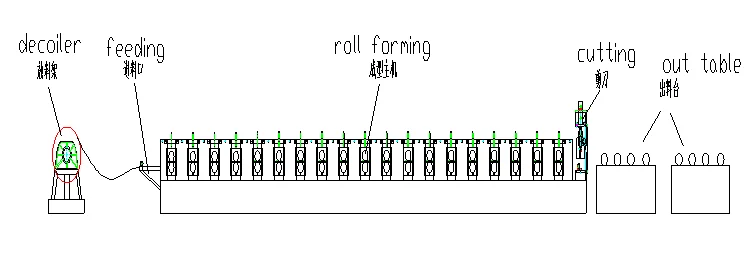

Profile, layout & production flow:

Material of the profile: Q195, Q235, GI or color steel

Thickness range: 0.5-1.2mm

Coil width: 1220mm

Height: 51±1,effective width: 972±5mm

Finished product length: from 500 mm to (at least) 12’000 mm

Layout of machine (only for reference, the exactly one will be send to customer in 20 days after confirmed order)

Working direction base on customer request:

The production flow of equipment:

Decoiler→ Feeding→roll forming→post cutting →out table

5T manual decoiler | ||

Dimensions: 1700mm*1000mm*800mm | ||

Width of feeding:1300mm | ||

Internal diameter of coil: variable, from 480 mm to 570 mm | ||

Maximum coil weight: 5000 Kg | ||

Mode of expand & fight :inner expand &fight by manua | ||

Way of feeding: manual | ||

Uncoiled metal compensator: included, assures even feeding at all production speed | ||

Color: Blue (or base on customer request) | ||

Feeding | ||

Adjustable center of the forming rollers and of sufficient length to prevent lateral movement of the strip on its entry to flattener. | ||

Feeding type: adjustable | ||

Feeding width range:1220 | ||

Entrance and guide roller: diameter is ¢65mm, material is SAE1045, surface with chrome | ||

Quantity: 1 | ||

Forming Section | ||

Material of the profile: Q195, Q235, GI or color steel | ||

Thickness range: 0.5-1.2mm | ||

Machine Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase | ||

Roll station:30 stations (according the final design) | ||

Roller material:ASTM1045 chrome plated surface with hardnesss,CNC, | ||

Shaft diameter: ¢85mm material: SAE1045 | ||

Machine roll forming speed:not less than 15m/min | ||

Transmission: by chain, one inch, double line | ||

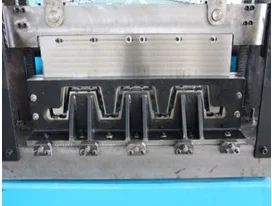

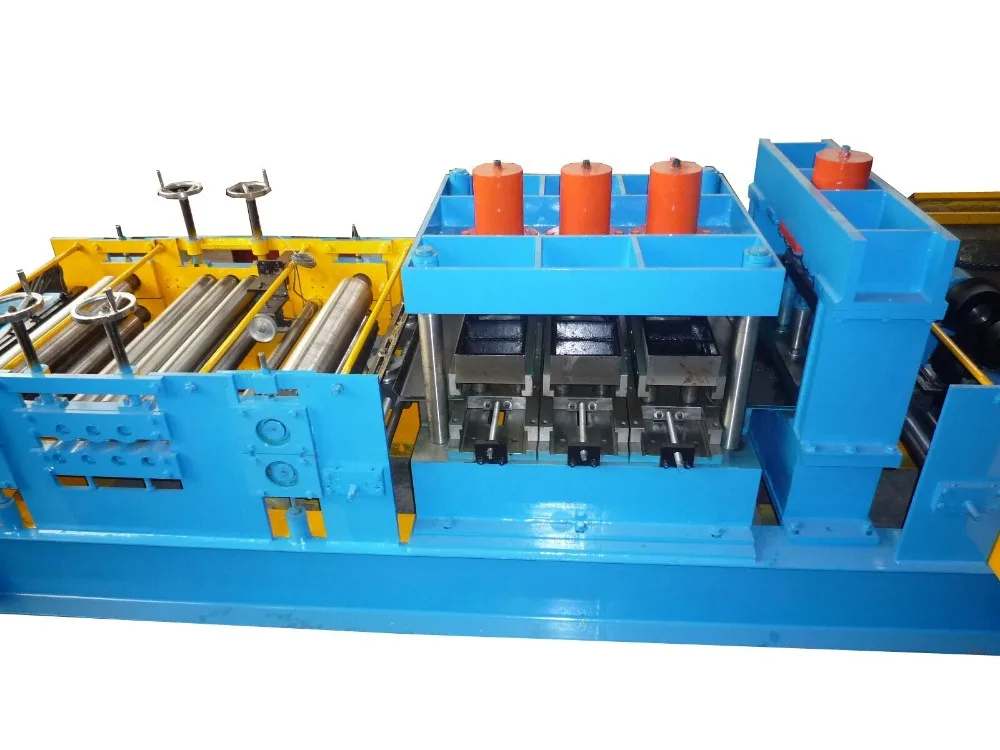

Post cutting system | ||

Profile transversal cutting device units allowing to cut the bent profile without damaging the metal coating and to assure a smooth cut included; | ||

Feeding of the last cut profile from the equipment: automatic if the length of the last profile is not less than 2000 mm; | ||

Cutting after forming: Cut the sheet after roll forming to required length | ||

Uses two hydraulic cylinders for operation shall include a flow regulator to achieve a uniform lowering knife. | ||

Material of blade:Cr12, 58-62 HRC hardness | ||

Output table: | ||

Frame: welding by tube | ||

Size: about 1.0m long*1.0mwide*0.9mhigh | ||

One out table with some support roller | ||

Supporter roller: ASTM 1045 with chrome | ||

Diameter of rollers: 55mm | ||

Color: Blue | ||

Quantity: 2units | ||

Hydraulic station | ||

Hydraulic power: 5.5kw | ||

Working pressure: 12Mpa adjustable | ||

Solenoid valve: 1 group | ||

Hydraulic oil: 46# hydraulic oil | ||

Color; Blue (or base on customer request) | ||

Quantity :1 | ||

Control desk | ||||||

Programmable setting of profile length and quantity | ||||||

Programmable cutting unit, various lengths in one programming cycle without quantity restrictions (without stopping the operating equipment): will be provided. 5groups datas canbe set in one time | ||||||

Automatic stopping of the equipment after completion of the cutting programme: will be provided. | ||||||

Operating system language: English and Chinese | ||||||

Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase | ||||||

Computer used to control length & quantity. Machine will automatically cut to length and stop when required quantity is achieved | ||||||

Length inaccuracy can be amended easily. | ||||||

Control panel: Button-type switch and touch screen | ||||||

Unit of length: millimeter (switched on the control panel) | ||||||

Frequency converter brand: Yaskawa | ||||||

Touch screen: Taiwan Weinview | ||||||

Color: gray | ||||||

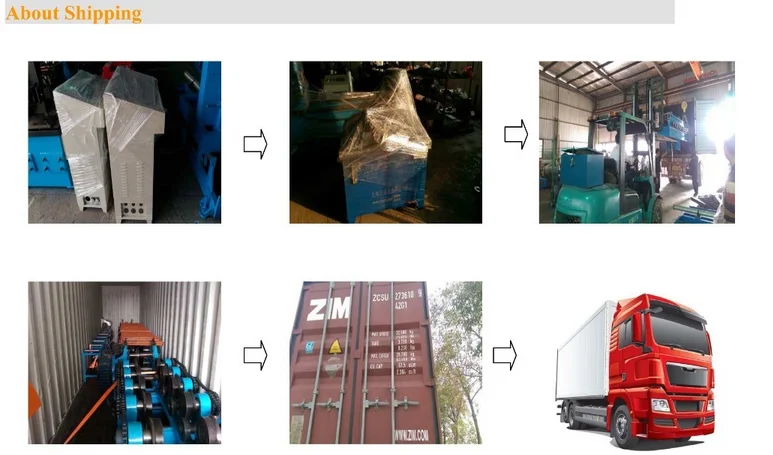

Pre-sales service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-sales service

S* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Products name with name

91.8% Response Rate

Products name with name

91.8% Response Rate

Products name with name

91.8% Response Rate

Product Categories : ROOF WALL PANEL ROLL FORMING MACHINE > DOUBLE LINES ROLL FORMING MACHINE

Premium Related Products