780 corrugated roofing sheet roll forming making machinery

Product Description

780 corrugated board color steel Roll Forming Machine

Equipment components:

Man-made uncoiler, Roll forming machine, computer control system, hydraulic control system, cutting

Our products are widely used in various industrial factory, civilian building, warehouse and easy steel building manufacturing, and have features such as nice appearance and durable.

Technical parameters: | ||

1 | Name of commodity & specification | XN-780 roof panel roll forming machine |

2 | Main motor power | 3kw |

3 | Hydraulic motor power | 3kw |

4 | Hydraulic Pressure | 10-12MPa |

5 | Voltage | 380V /3phase/ 50 HZ (or as your requirement) |

6 | Control System | PLC Delta Inverter |

7 | Main Frame | 300mm H-Beam |

8 | Side panel Thickness | 14mm |

9 | Chain Size | 20mm |

10 | Feeding Material | color steel coils, Galvanized sheet, aluminium coils |

11 | Feeding Thickness | 0.3-0.8 mm |

12 | Feeding Width | 1000mm |

13 | Effective width | 780mm |

14 | Productivity | 8-12m/min |

15 | Roller Station | 16 |

16 | Roller Diameter | 70mm |

17 | Roller material | 45# steel |

18 | Cutter material | Cr12 , quenched |

19 | Cr-Plating Size | 0.05mm |

20 | Overall Size | 7600×1300×1100mm |

21 | Total Weight | 4T |

22 | Components | Manual Uncoiler-------------------1 set |

23 | Workflow | Manual decoiling----feeding and guiding----roll forming----cut to length----run out table |

24 | Package | Main machine is nude in the container |

25 | Minimum order quantity | 1 set |

26 | Payment terms | T/T(30% T/T pay in advance, the remaining 70% pay before ship) |

27 | Delivery time | 30 working days later after deposit |

Our machine | Influence of the machine | |

| Main forming machine body | High strength H350 or H400 steel. machine through milling machine after welding | Sturdy and durable, ensure the plate standard |

| Material of the roller | High grade No.45 forged steel | Ensure the forming effect of the panel and the use age will be longer,the surface of the panel |

| Material of the cutting | GCr12 steel with quenched treatment | Cutting is out of shape not easily and use age will be longer,the panel size precision |

| Material of the active shaft | High grade solid No.45 carbon steel, Shaft diameter is 72mm. | Improve the integrated mechanic feature of the shaft and keep product standard |

Control system | PLC control system,some elements are imported from Japan and Germany | Machine become more accurate and more stable |

Terms of Payment: 30% of the total contract value paid by T/T as down payment, the rest 70% of the total contract value to be paid by T/T after inspection by buyer in seller's factory while before delivery.

Delivery: 30 days after receipt of advance payment

Service: we send technician to your country to fix the machine.The buyer should bear all the cost including: visa, Round trip tickets and suitable accommodation, also buyer should pay salary 60USD/day.

Warranty: 12 months limited warranty

During warranty: parts are free but buyer pay for the shipping fee

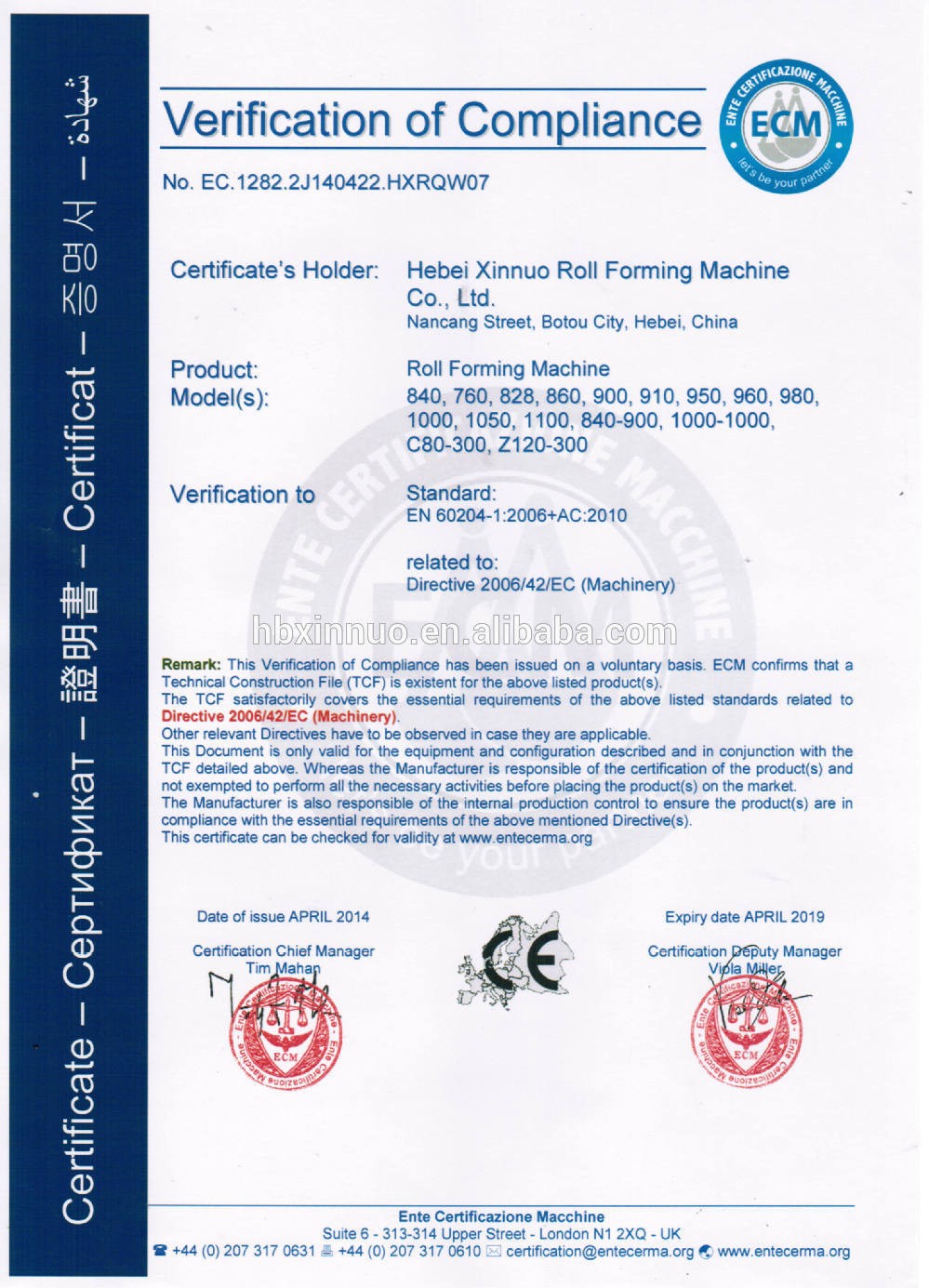

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Our machines feature beautiful appearance, long service life, good performance, simple operation, reasonable price, good quality and so on.

Strong technical resources are the most stable guarantee for our products' quality. We adopt computer software for design drawing, production drawing and installation drawing for steel construction equipment. We adopt advanced computer digital inspection and produce high quality light steel structure equipment. Our technical is updating day by day!

Our sales network covers all over China. We also sell products to the United States, Australia, the Netherlands, Germany, Ecuador, Bolivia, Thailand, Malaysia, Indonesia, India, the Philippines, Bangladesh, Nigeria, South Africa, Ethiopia, Syria, Libya, Ghana, Sudan, Saudi Arabia, the United Arab Emirates, Turkey, Azerbaijan and other markets.

Our company has matured after-sale service network, we could provide efficient and satisfactory service for you throughout the period of our cooperation.If necessary, we can supply you with local technical support and send technicians to for installation and operation training.

The Canton Fair

1:How to play order:

Inquiry---confirm the profile drawings and price----confirm the PI---arrange the deposit or L/C---then OK

2:How to visit our company:

Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can pick up you.

Fly to Shanghai Airport:

By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours),then we can pick up you.

3:When we exported the machines:

We have beening making and exporting the machines since from the year of 1998.

Contact us if you need more details on Roofiing Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Making Machinery、Roofing Tile Making Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Roof Panel Forming Machine > Corrugated Roofing Tile Machin